-

- About us

- Contact Us

-

Contact person: Joshua Fan

Whatsapp: +8618229723668

Email: 18229723668@139.com

Product Description:

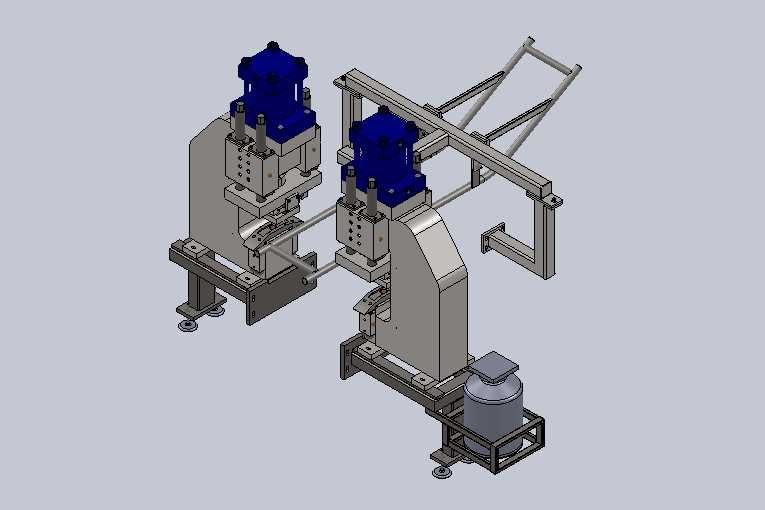

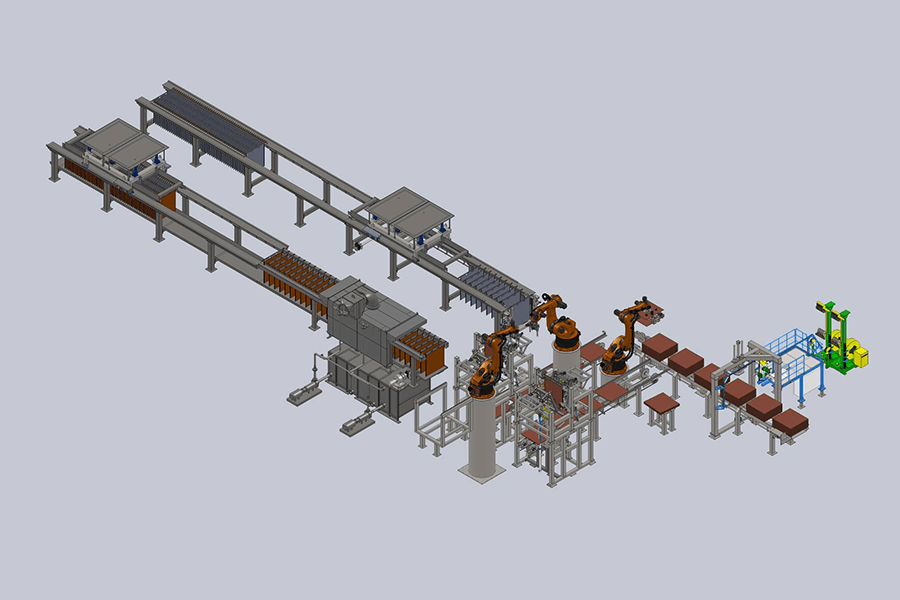

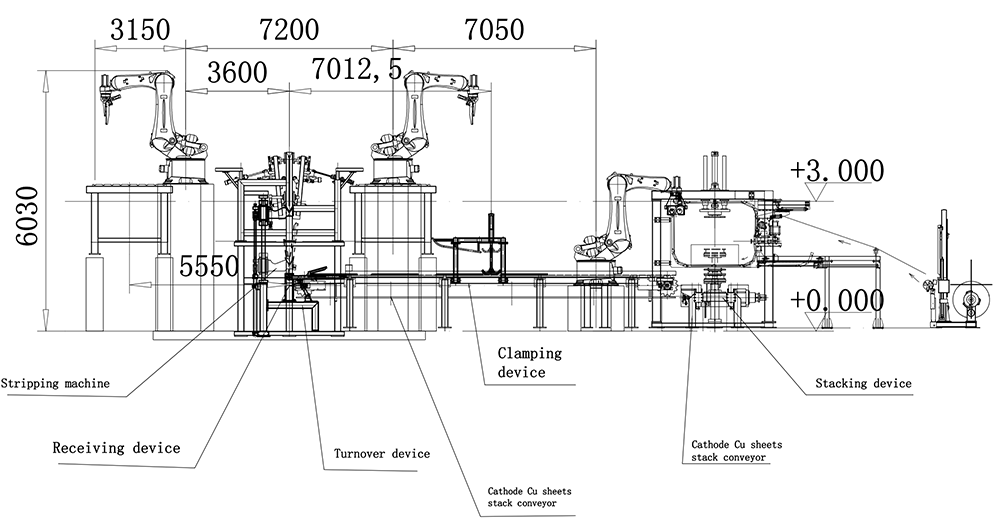

The stripping machine is the key equipment of Cathode Washing and Stripping System. It can strip the electro-deposited copper layers or electro-deposited copper layers from the stainless steel (SS) cathode. Generally, it works together with robot to complete the work.

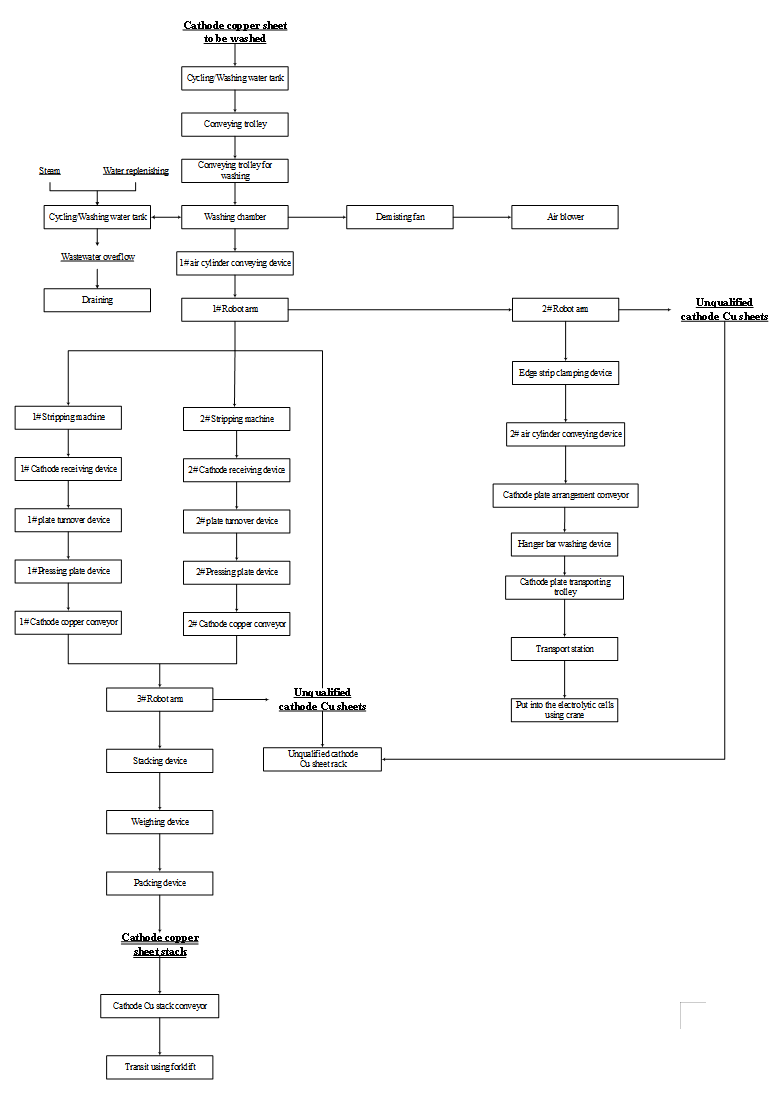

Main Process:

Parameters:

| S/N | Item | Index | Remark |

| 1. | Design Capacity | 1 cathode plate /6.54s | 550 cathode plates/hour |

| 2. | Processing capacity | 1 cathode plate /7.2 s | ≥500 cathode plates/hour |

| 3. | Washing water temperature | ≤60~70℃ | 60~65℃ recommended |

| 4. | Washing water circulation volume | three-phase washing, two circulating pumps | 1#The pump's flow is 90m3/h, 2# pump's flow is 70m3/h, one 12m3 Cycling/Washing water tank. |

| 5. | Dimensions (L×W×H) | 45200×16700×6000mm | Actual dimension is subject to the finalized design. |

| 6. | Stack number | according to copper sheet stack quantity and height | |

| 7. | Stripping Specifications | 945mm×1000mm×(5~10)mm | weight of deposited copper sheet on the one cathode plate side is 45~90 kg. |

| 8. | Control method | PLC | |

| 9. | Safety device | Emergency interlocks and safety devices, it prevents personal injury and equipment damage under any conditions. | |

| 10. | Cathode lifting method | As per the special cranes lifting requirements for for electrolysis plant. | |

| 11. | Main power supply | 380V AC(±10%), 50Hz | |

| 12. | Safety control voltage | DC 24V | Buttons, indicator lights, hydraulic solenoid valve control power, etc. |

| 13. | Total installed power | 293.8kW | |

| 14. | Total weight | 107 tons | |

| 15. | Hydraulic working pressure | 11.0 MP | |

| 16. | Cooling water consumption | 9t/h | Water pressure 0.2~0.4MPa, to cool hydraulic oil. |

| 17. | Water vapor consumption | 331.4m3/h | |

| 18. | Water vapor pressure | 0.6~0.8 MPa | |

| 19. | Demisting fan | 8,000 m³/h | wind pressure 1500 Pa |

| 20. | Compressed air consumption | 0.4 t/h | Air pressure: 0.3 MPa |

| 21. | Cathode copper stack transport mode | Using forklift | |

| 22. | Operational modes | Continuous Mode Automatic Mode Manual Mode | Test Mode The operational modes can be realized by switching the operating console switches. |

| 23. | Washing effect | As per LME Grade A copper requirements | After washing, the cathode copper surface is clean without electrolyte, CuSO crystal, and other attachments. |

| 24. | Main Equipment Design Life | 30 years | |

| 25. | Working Day Per Year | 360 days | |

| 26. | Daily shifts | 3 shift | |

| 27. | Working Hours Per Shift | 8 hours |

FAQ:

Q1: What's payment terms are acceptable?

A: LC, TT and cash.

Q2: Can you provide installation service?

A: Yes, we provide the clients with installation service or installation instruction through on-line or other method as per their needs.

Q3: Can you provide design service to client?

A: Yes, we can provide customized design service and stripping machine as per clients needs.

Q4: Does the busbar can work alone?

Yes.

Hot tags: Zinc Stripping machine, copper stripping machine, robot, Electrolysis cell, anode, cathode, copper refining, zinc refining, lead refining.