- Home

- Products

-

Electrolytic Cell

Electrolytic cell, also know as electrolysis cell, electrolytic bath, electrowinning cell, electrowinning tank and other terms. Nowadays, the vinyl resin and silica sand are widely employed to build the electrolytic cell. As a result, the electrolytic cell built using the vinyl resin and silica sand is called polymer concrete electrolytic cell or vinyl resin electrolytic cell. Unlike the conventional electrolytic cell, which is build using acid resisting binder cement, the polymer concrete electrolytic cell’s service life is longer and easy to maintain and repair.

-

Anode

Anode that is a hydrometallurgy device is employed to refine copper, zinc and other metals through electrolysis or electrowinning. The anodes for copper electrolysis or lead electrolysis are made of crude copper (≥98% Cu) or crude lead(≥98% Pb) in the plant using the ingot smelting and casting equipment. We also can supply the copper and lead anode production equipment.

-

Cathode

Cathode that is a hydrometallurgy device is employed to refine copper, zinc and other metals through electrolysis or electrowinning. The cathode plates refining copper or zinc are made of 316L stainless steel, and the cathode hanger bar is made of refined copper. The cathode made of stainless steel is also known as the permanent cathode.

-

Lead-tin-antimony Vacuum Distillation Furnace

The lead-tin-antimony vacuum distillation furnace (Pb-Sn-Sb VDF) is the key pyro-metallurgy equipment to extract the tin from the lead-tin alloy.

The Pb-Sn-Sb VDF working method similar to the petroleum vacuum distillation unit, which separate gasoline, diesel oil and other materials from the crude oil. -

Lead Pot

Lead pot, also known as lead kettle, is a lead(Pb) pyro-refining device that is utilized to remove the impurities in the lead to produce the refined lead and collect the slag. Lead pot/kettle is the key equipment for spent lead battery recovery.

The lead pot (kettle) system comprises of agitator, kettle cover, kettle, stove and platform. The refractory brick block are built inside the stove body. We can design and supply complete lead pot system to the client. -

Tin Pot

Tin pot, also known as tin kettle, is a Tin (Sn) pyro-refining device that is utilized to remove the impurities in the tin. Tin pot/kettle is the key equipment for refining tin.

The tin pot is employed to removed the impurities like copper (Cu), antimony(Sb), arsenic(As) and others before/after tin vacuum distillation or before tin crystallization to produce refined tin(≥99.99%). -

Agitator

The agitator is the metallurgy device stirs the melted lead or melted tin in order to form dross and remove impurities.

Materials: Q245R, Q345R, SS304, stainless steel 316L, special refractory.

Motor power: 1~10kW

Weight: Varies according to capacity

Service life: 12-36 months -

Molten Metal Pump

Molten metal pump, also known as lead pump, tin pump, and zinc pump, is a metallurgy device employed to continuously transport the molten lead, tin, zinc to the desired place for further process.

Materials: Q245R, Q345R, SS304, stainless steel 316L, special refractory.

Motor power: 1~10kW

Weight: Varies according to capacity

Service life: 6-24 months -

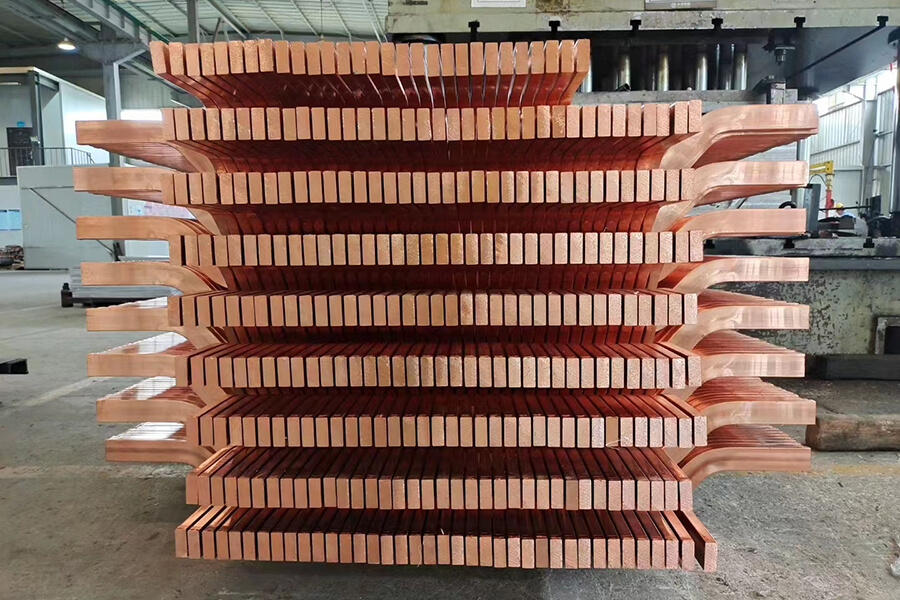

Busbar

Busbar, or copper busbar, which convey the low voltage and high current to the anode and cathode inside the electrolysis cell to refine copper, zinc, silver and other metals, is the key device for electrolysis equipment or hydro-metallurgy.

-

Stripping Machine System

The stripping machine is the key equipment of Cathode Washing and Stripping System. It can strip the electro-deposited copper layers or electro-deposited copper layers from the stainless steel (SS) cathode. Generally, it works together with robot to complete the work.

-

Rectiformer

Rectiformer, also known as rectifier transformer, changes high voltage AC current into low voltage DC current to produce refined copper, refined zinc, refined silver and other refined metal, as well as Caustic Soda, Sodium Chloride, Chloride Dioxide. It also works as the DC heating power supply for production of graphite and carborundum.

-

Tilting Furnace for Smelting Scrap Copper

Tilting furnace for smelting scrap copper is widely used in copper and aluminum refining. We are skilled at producing tilting furnace from 1.5~360 ton(even larger).

Tilting furnace for copper can work as the anode furnaces, holding furnaces, or Peirce Smith converters in copper refining industry. The molten copper is cast into crude copper ingot or copper anode plate for electro-refining. -

Cobalt Removal Reagent

Cobalt removal chemical is widely used in Zinc hydrometallurgy process.

The Cobalt removal reagent mainly used to purify the impurities such as Co, Ni and Cd from the leaching solution of Zinc hydro metallurgy process. -

Fluorine Removal Reagent

Flurine(F) removal reagent, also known as defluorinating agent, is widely used in Zinc hydrometallurgy process.

LJM-CL1 Fluoride (F) removal agent is used to remove Fluoride(F) impurity of hydrometallurgy Zn solution (ZnSo Solution). F removal agent that can remove F impurity of hydrometallurgy Zn solution (ZnSo Solution) is a compound inorganic chemistry. -

Chlorine Removal Reagent

Chlorine(Cl) removal reagent, also known as dechlorinating reagent, is widely used in Zinc hydrometallurgy process.

Chlorine(Cl) removal reagent is used to remove Chlorine(Cl) impurity of hydrometallurgy Zn solution (ZnSO Solution). Cl removal agent that can remove Cl impurity of hydrometallurgy Zn solution (ZnSO Solution) is a compound inorganic chemistry.