Company

Hunan Zhongda Nonferrous Metals Metallurgy Precision Technology Co.,LTD, an affiliate of Research Institute of Resource Recycling Central South University (CSU), focuses on the metallurgy project and equipment design.

Company purpose: Simplified metallurgy process to refine metal

- 1. Metallurgy project solution design: Assess and design metallurgy project, provide complete equipment for metallurgy project.

- 2. Vacuum metallurgy equipment: Nonferrous metal vacuum separate equipment and nonferrous metal vacuum refining equipment

Service and products:

- 3. Atmospheric metallurgy equipment: Main nonferrous metal smelting equipment, including flexible belt furnace, rotary furnace, imperial smelting furnace, high-end intermediate frequency furnace;

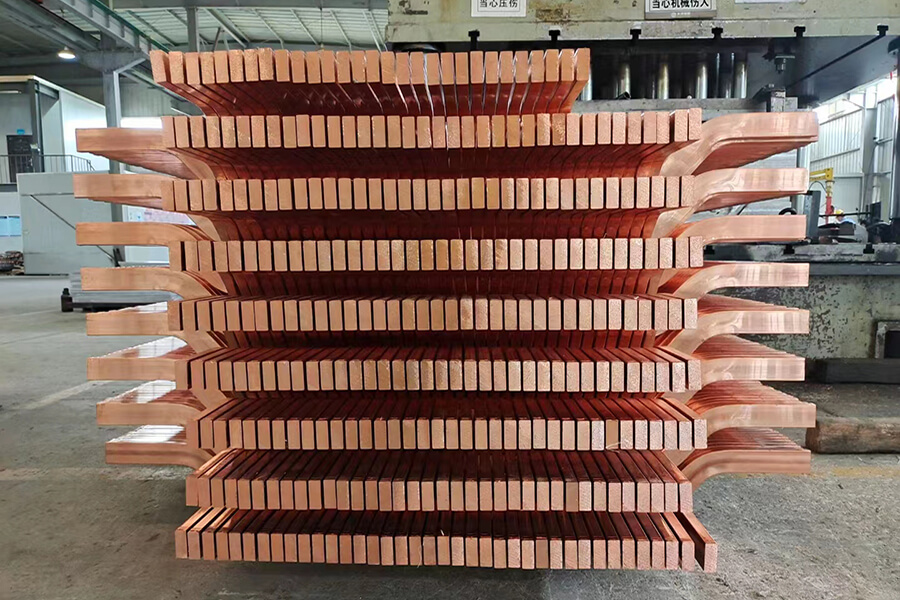

- 4. Hydrometallurgical equipment: electrolytic cell, busbar, rectiformer, control panel;

- 5. Environmental protection equipment: off-gas treatment equipment, including Cd, Zn, Cu smelting off-gas treatment equipment;

- 6. High-end material: Flake zinc dust, distilled zinc dust, blowing zinc dust, Zn, Te, As, and other high purity metal materials.

FAQ

Q1: What's payment terms are acceptable?

A: LC, TT and cash.

Q2: Can you provide installation service?

A: Yes, we provide the clients with installation service or installation instruction through on-line or other method as per their needs.

Q3: Can you provide design service to client?

Yes, we can provide customized design service as per clients needs.

......