Indium Refining Project

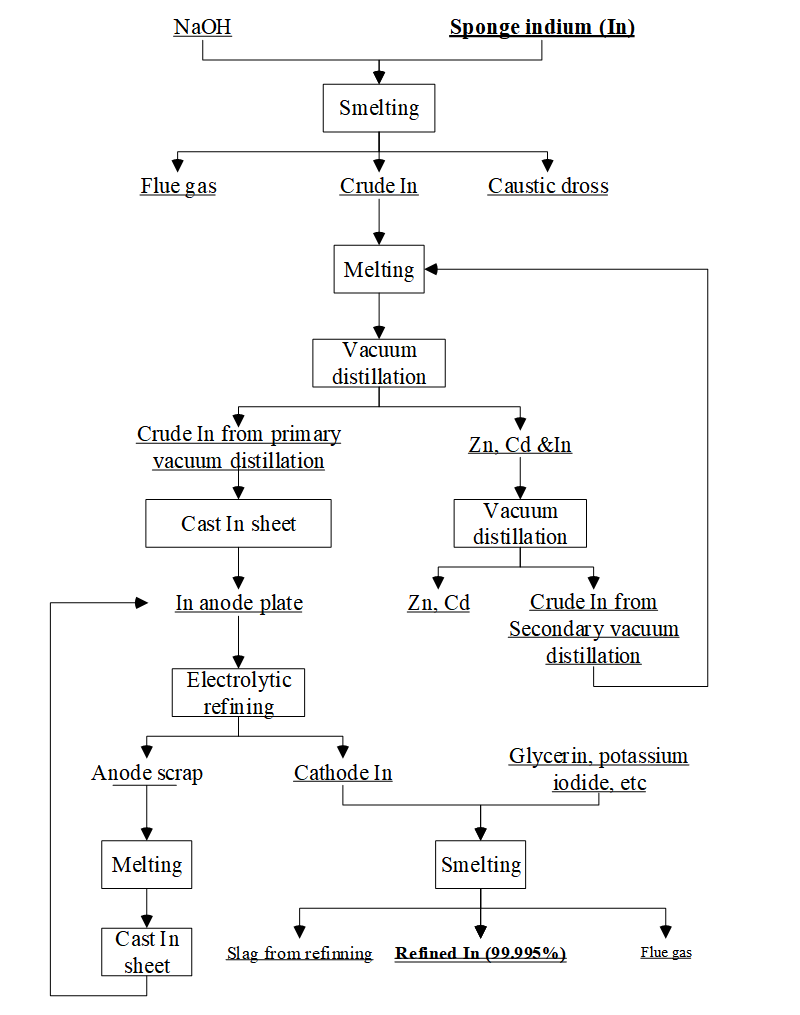

This indium refining project is design to extract the Indium (In) from the sponge indium (sponge In), which is the residual from the zinc (Zn) refining. There are two stages for refining In. At first stage, it reduces sponge In to produce the crude Indium (95~96% Cd); at second one, the crude Cd is refined by using Indium vacuum distillation furnace.

Process

Crude In Reduction Furnace Technical Index

| No. | Item | UOM | Description |

| 1. | Raw material | Sponge In | |

| 2. | Crucible effective volume | Kg | 500 |

| 3. | Charging method | Manually charge, tilting furnace discharging | |

| 4. | Max capacity | kg/batch | 300 |

| 5. | Max temperature | ℃ | 800 (Outside crucible) |

| 6. | Heating energy | AC three-phase 380V 50Hz | |

| 7. | Flue gas discharge method | furnace roof side face | |

| 8. | Heating method | Indirect heating crucible | |

| 9. | Furnace lining material | castable + folding gasket | |

| 10. | Electric furnace power | kW | 60 |

| 11. | Heating element | Heating wire | |

| 12. | Furnace temperature uniformity | ℃ | ±5 |

| 13. | Temperature rising time | h | ≤1 |

| 14. | Temperature control point | Piece | 2 |

| 15. | Temperature measurement point | Piece | 2 |

| 16. | Furnace wall temperature rise | ℃ | ≤45 |

| 17. | Crucible material | 316 L | |

| 18. | Crucible outer diameter | mm | Φ440 |

| 19. | Crucible wall thickness | mm | 20 |

| 20. | Furnace body diameter | mm | φ1100 |

| 21. | Furnace height | mm | 1500 |

| 22. | Temperature control method | Intelligent temperature control, automatic alarm |

Basic design parameters for indium vacuum distillation furnace:

| Raw material chemical composition | In | Cb | Fe | Tl | Sn | Al | ||

| ≥95% | 0.5~1% | 0.5~1.5% | 0.5~0.8% | 0.2~0.6% | 0.02~0.03% | |||

| Product | Refined Sn ingot | 100 t/a (In≥99.9%) | ||||||

| Working days per year (day) | 300 | |||||||

| Annually treating capacity (tpa) | 350 tone | |||||||

| Fuel | Electricity | AC 380V 50Hz | ||||||

Note:

1. The actual raw material chemical composition should be supplied by clients.

2. The raw material chemical composition in the above table is decided with reference to the ones’ chemical composition in China and India.

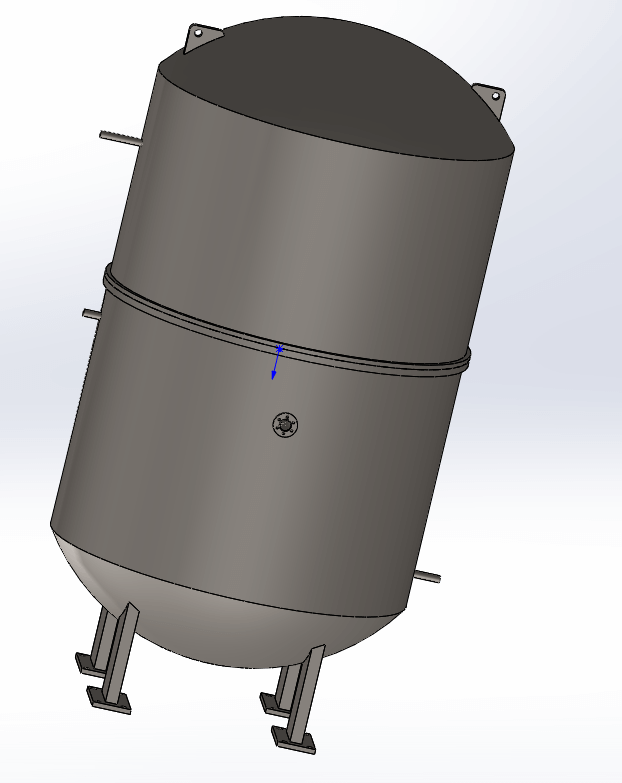

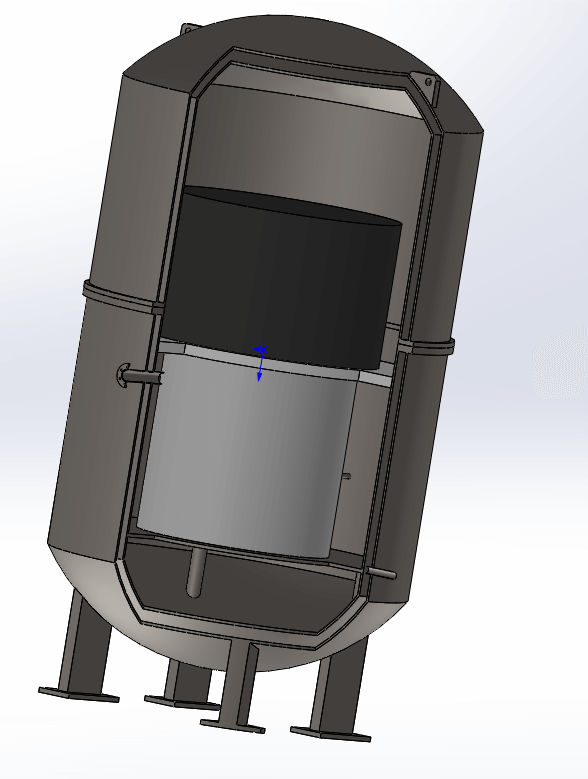

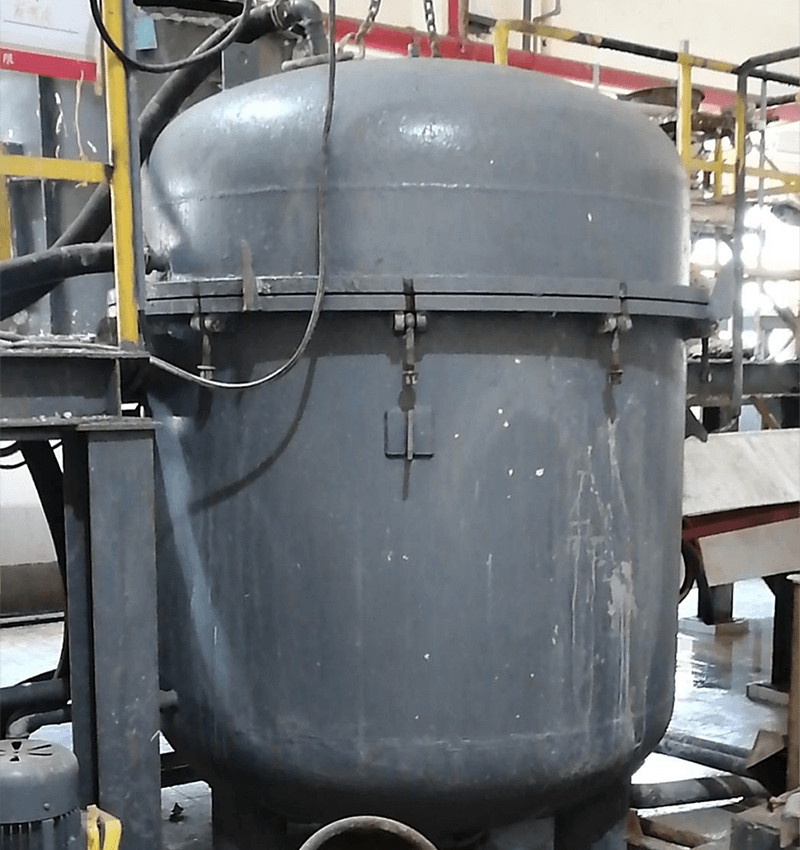

In vacuum distillation furnace technical indexes:

| S/N | Item | UOM | Description |

| 1. | Capacity | kg/batch | 300 kg/batch |

| 2. | Process mode | Refine In batch by batch | |

| 3. | Operation interval | hour/batch | 8~12 |

| 4. | Heat mode | Medium frequency induction heating | |

| 5. | Rated power | kW | 120 |

| 6. | Crucible type | Enclosed refining crucible | |

| 7. | Crucible material | Graphite | |

| 8. | Crucible service life | over 12 months | |

| 9. | Cooling method | Vacuum radiation heat transfer, water cooling furnace casing | |

| 10. | Output material | In ≧99.1% | |

| 11. | Purification rate | Zn & Cd removal rate >98% | |

| 12. | Vacuum degree | furnace body vacuum degree 0~100Pa | |

| 13. | Vacuum pump | rotary-vane vacuum pump, 3kw | |

| 14. | Manpower | 2 persons for one shift | |

| 15. | Circulating cooling water | t/h | 20 |

| 16. | Water consumption | t/day | 1 |

Note: The above indexes are the Sponge In Reduction Furnace and In vacuum distillation furnace design parameter as per Chinese clients’ requirements.

FAQ:

Q1: What's payment terms are acceptable?

A: LC, TT and cash.

Q2: Can you provide installation service?

A: Yes, we provide the clients with installation service or installation instruction through on-line or other method as per their needs.

Q3: Can you provide design service to client?

A: Yes, we can provide customized design service and product as per clients needs.

Q4: What are the raw materials and final product of the project?

A: The raw materials are the sponge cadmium, which is the residual from zinc refining. The final product is refined Indium (≥99.9% Indium).

Hot tags: sponge indium reduction, crude indium reduction, indium refining, indium distillation furnace, indium vacuum pyrorefining, cadmium vacuum distillation furnace, zinc slag treatment, Indium vacuum distillation furnace, refined indium.