Cadmium Refining Project Solution

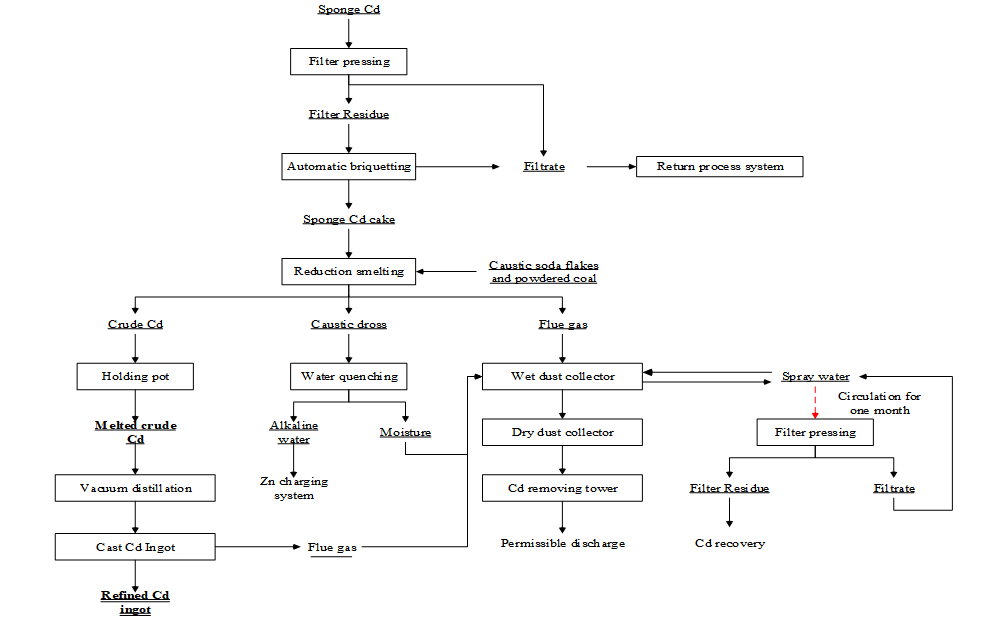

This Cadmium refining project is design to extract the cadmium (Cd) from the sponge cadmium (sponge Cd), which is the residual from the zinc (Zn) refining. There are two stages for refining Cd. At first stage, it briquettes and reduces sponge Cd to produce the crude cadmium(98~99% Cd); at second one, the crude Cd is refined by using cadmium vacuum distillation furnace.

Basic design parameters:

| Raw material (Sponge Cd) chemical composition* | Cd | Zn | Pb | As | Ni | Co | Moisture | |

| ≥60~80% | <5% | <0.5% | <0.5% | <0.8% | <1% | ≤15~18% | ||

| Product | Refined Sn ingot | 2,500 t/a (Sn≥99.995%) | ||||||

| Working days per year (day) | 330 | |||||||

| Annually treating capacity (tpa) | Spong Cd | 4,000 t/a | ||||||

| Fuel | Electricity | AC 380V 50Hz | ||||||

*Note:

1. The actual raw material chemical composition should be supplied by clients.

2. The raw material chemical composition in the above table is decided with reference to the ones’ chemical composition in China and India.

2.1 Refined Sn ingot production process

Technical and Economic Index

| S/N | Item | UOM | Parameter | Remark |

| 1. | Output | Ton/day | ≥4t | |

| 2. | Cd recovery rate | % | ≥99.5 | |

| 3. | Bottom slag Cd content | % | ≤80% | |

| 4. | Refined Cd | % | 99.995 | |

| 5. | Power consumption for refined Cd | kWh/t refined Cd | ≤750 | |

| 6. | Melting furnace and holding furnace's comprehensive power consumption | kWh/t refined Cd | ≤75 | |

| 7. | Caustic soda(NaOH) consumption | kg/t refined Cd | ≤220 |

Main Sub-systems:

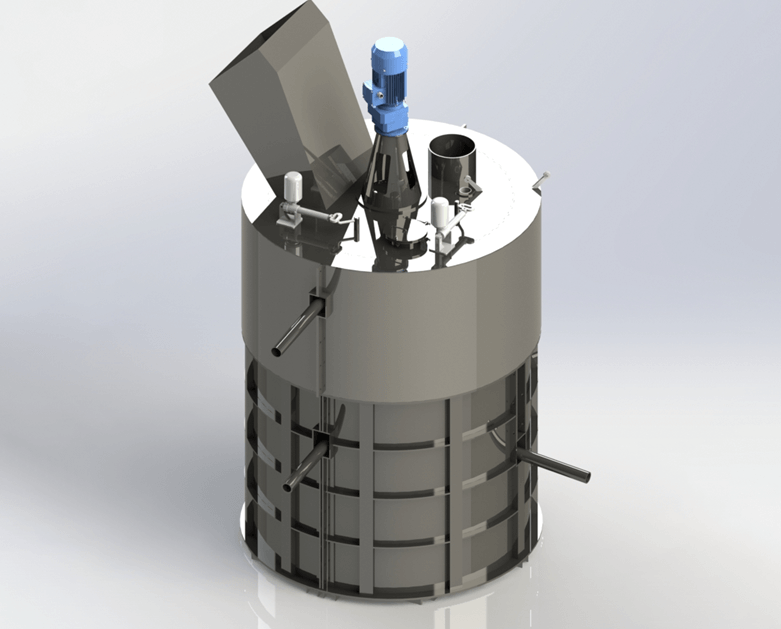

1) Sponge Cd briquetting sub-system

2) Sponge Cd charging sub-system

3) Sponge Cd reduction sub-system

4) Refined Cd distillation sub-system

5) Cast refined cadmium ingot sub-system

6) Alkali slag water quenching sub-system

7) Flue gas collection and treatment sub-system

8) Electric control sub-system

-

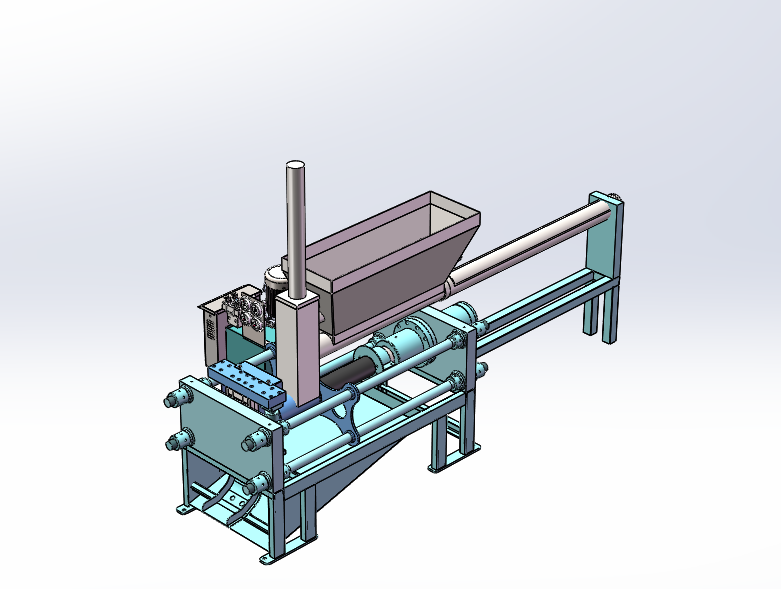

Sponge Cd Briquetting Sub-system

-

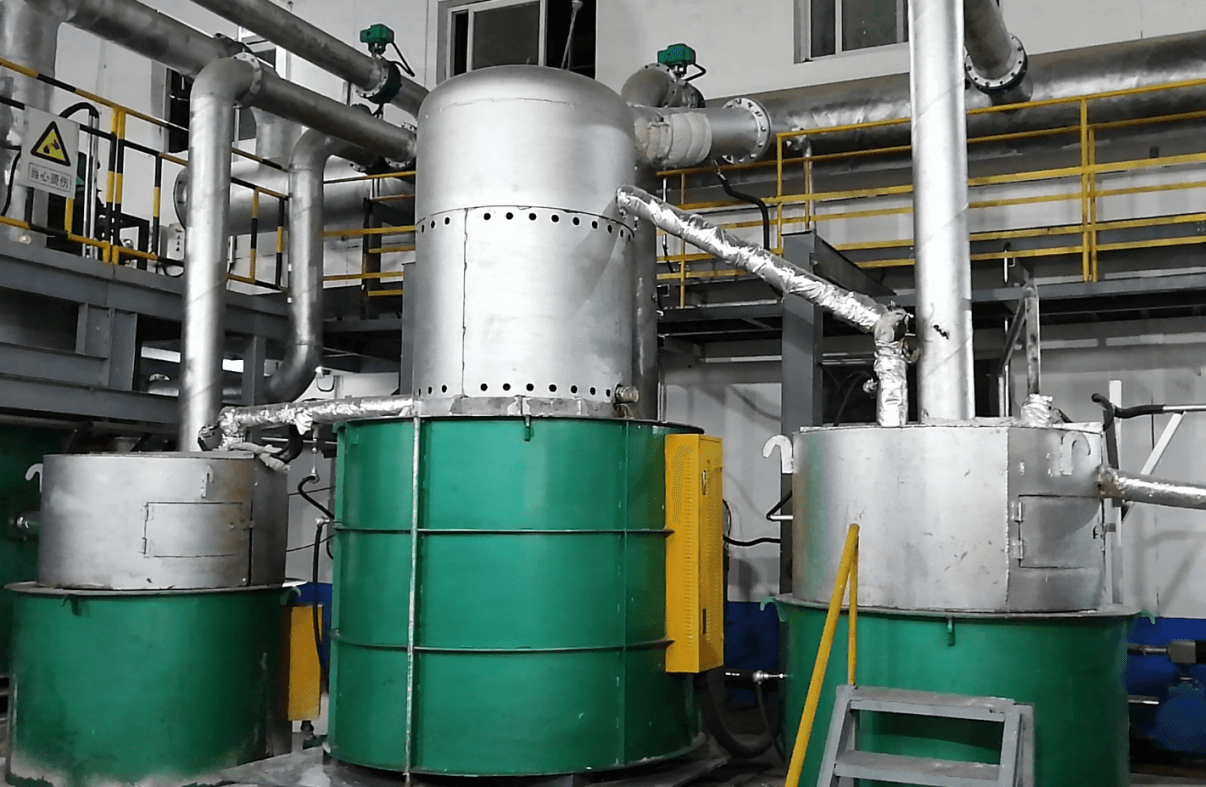

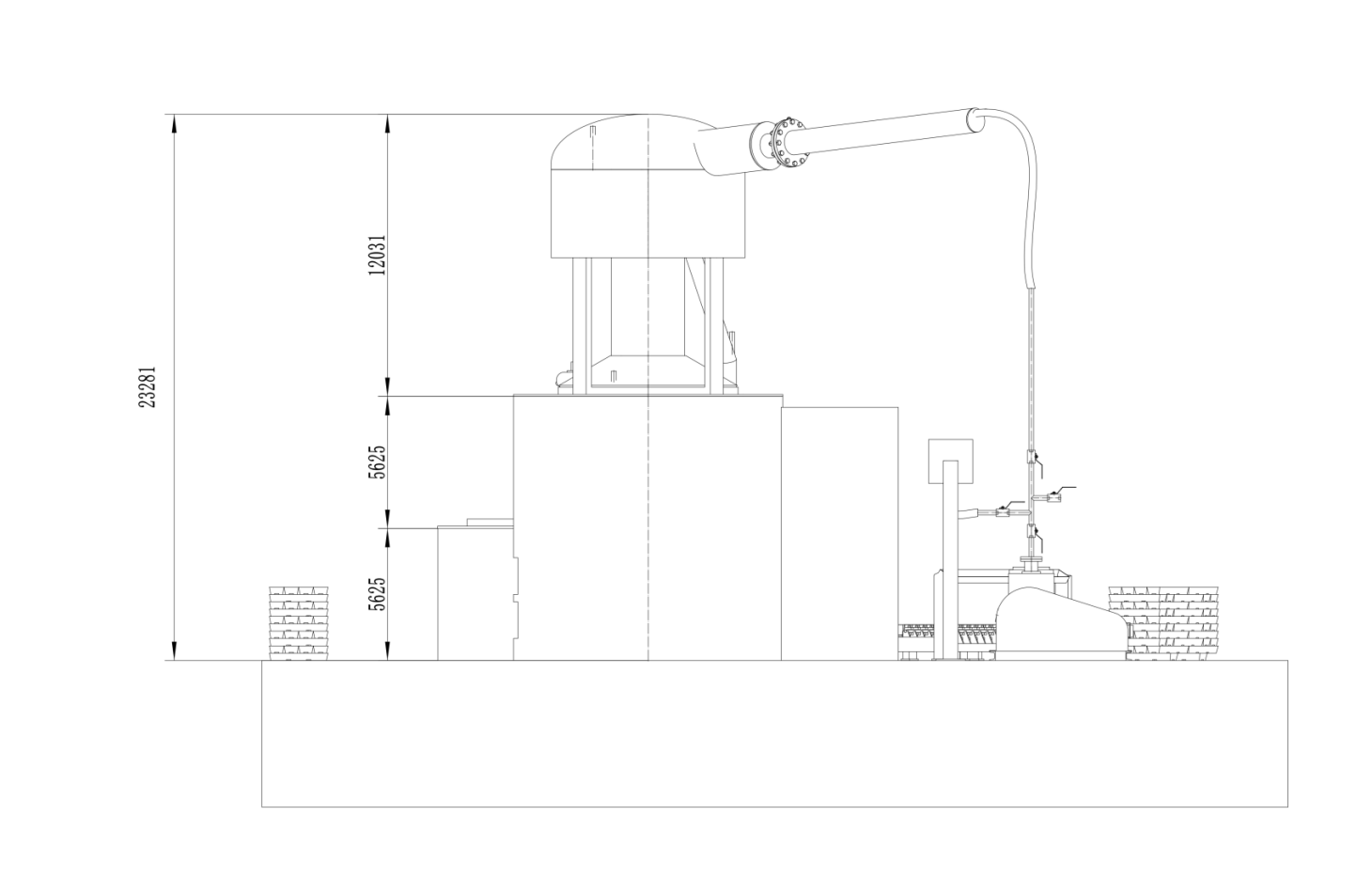

Sponge Cd Reduction furnace

Equipment list

| No. | Item | QTY | Remark |

| 1. | Sponge Cd briquetting machine | 1 | |

| 2. | Sponge Cd cake charging equipment | 1 | |

| 3. | Sponge Cd reduction furnace | 1 | |

| 4. | Cd vacuum distillation furnace | 1 | |

| 5. | Refined cadmium ingot casting machine | 1 | |

| 6. | Flue gas collecting equipment | 1 | |

| 7. | Electric control equipment | 1 |

FAQ:

Q1: What's payment terms are acceptable?

A: LC, TT and cash.

Q2: Can you provide installation service?

A: Yes, we provide the clients with installation service or installation instruction through on-line or other method as per their needs.

Q3: Can you provide design service to client?

A: Yes, we can provide customized design service and product as per clients needs.

Q4: What are the raw materials and final product of the project?

A: The raw materials are the sponge cadmium, which is the residual from zinc refining. The final product is refined cadmium(≥99.9% Cd).

Hot tags: sponge cadmium reduction, crude cadmium reduction, cadmium refining, cadmium distillation furnace, cadmium vacuum pyrorefining, cadmium vacuum distillation furnace,zinc slag treatment, zinc residual treatment, sponge cadmium, refined cadmium.