Lead-tin Recovery Project

The lead-tin recovery project is design to extract the tin metal from the lead-tin alloy(Pb-Sn Alloy) or lead-tin-antimony alloy(Pb-Sn-Sb alloy), which are the slag from the crude lead refining or lead acid battery recovery. The lead-tin-antimony is the core metallurgy equipment of the project.

Basic design parameters:

| Raw material chemical composition* | Sn | Sb | Pb | As | Cu | Ag | PbO | |

| 55~30% | 1~3% | 70~90% | 0.0069% | 0% | 800~1200PPM | Unknown | ||

| Product | Refined Sn ingot | 1,500 t/a (Sn≥99.9%) | ||||||

| Crude Pb ingot | 3,500t/a | |||||||

| Working days per year (day) | 3000 | |||||||

| Annually treating capacity (tpa) | 5,000 tone | |||||||

| Fuel | Electricity | AC 380V 50Hz | ||||||

*Note: This raw material is for reference. The client must give us the raw material chemical composition before making the project design.

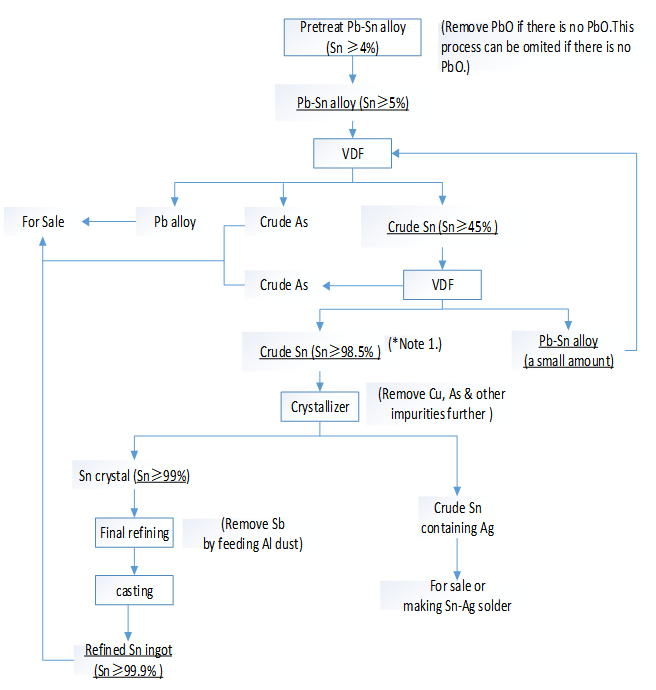

Process:

Technical and Economic Index

| № | Item | UOM | QTY | Remark |

| 1. | Refined Sn | T/month | 125 | |

| 2. | Crude Pb Alloy | T/month | 300 | |

| 3. | Al dust consumption | kg/month | 300 | Depend on raw material chemical composition |

| 4. | Ammonium chloride consumption | kg/month | 350 | |

| 5. | Sulfur (S) consumption | kg/month | 580 | |

| 6. | Sawdust fluxing agent | kg/month | 420 | |

| 7. | Sn metal recovery rate | % | 98.5 | |

| 8. | Pb metal recovery rate | % | 99 | |

| 9. | Water consumption for production | m3/d | 30-40 | (1)30-40 m3/d water is a calculated value. (2)The water is used as cooling water. (3)The water should not be drained to sewer and could be reused after cooling. (4)There should be a water pool in the plant for recycling and cooling the water. |

| 10. | VDF rated power | kW | 500 | |

| 11. | Crystallizer rated power | kW | 140 | |

| 12. | Tilt agitator rated power | kW | 19 | |

| 13. | Sn pump rated power | kW | 3 | |

| 14. | Working days per year (day) | Day/year | 300 |

Equipment list

| No. | Item | Specification | QTY | Remark |

| 1. | Lead-tin vacuum distillation furnace | 15T/Day | 1 set | |

| 2. | Continuous crystallizer | 15T/Day | 1 set | |

| 3. | Sn ingot cast machine | 30 molds 10 ton per day | 1 set | |

| 4. | Impurity removing pot (With water cooling jacket) | 10Ton Q235 steel | 1 pcs | Platforms are prepared by client as per our drawings. |

| 5. | Holding pot | 10Ton Q235 steel | 1 pcs | |

| 6. | Casting pot | 10Ton Q235 steel | 1 set | |

| 7. | Agitator | 5.5 kW | 2 set | |

| 8. | Sn pump | 3 kW | 6 set | 3 operation, 3 standby |

FAQ:

Q1: What's payment terms are acceptable?

A: LC, TT and cash.

Q2: Can you provide installation service?

A: Yes, we provide the clients with installation service or installation instruction through on-line or other method as per their needs.

Q3: Can you provide design service to client?

A: Yes, we can provide customized design service and product as per clients needs.

Q4: What are the raw materials and final product of the project?

A: The raw materials are the lead-tin alloy(Pb-Sn Alloy) or lead-tin-antimony alloy(Pb-Sn-Sb alloy), which are the slag from the crude lead refining or lead acid battery recovery. The final product is the refined tin metal(≥99.9% Sn).

Hot tags: lead-tin separation, tin extraction, lead-tin-antimony vacuum distillation furnace, lead-tin alloy treatment, lead-acid battery recovery slag treatment, crude lead refining, Pb-Sn VDF, vacuum distillation, tin refining, Pb-Sn-Sb VDF, refined tin metal.